Plan ahead to avoid massive overhauls & costly downtime

It’s one of the certainties of a data center that equipment will age and eventually break down. Every component has a lifecycle that can help you determine when it might be time to upgrade. And with technology evolving so quickly, it’s more important than ever to prepare for future changes and put your company in the best possible position to handle equipment EOL (end of life) situations. By implementing a hardware lifecycle management plan, you can avoid problems associated with inoperable or obsolete equipment.

The importance of having a plan

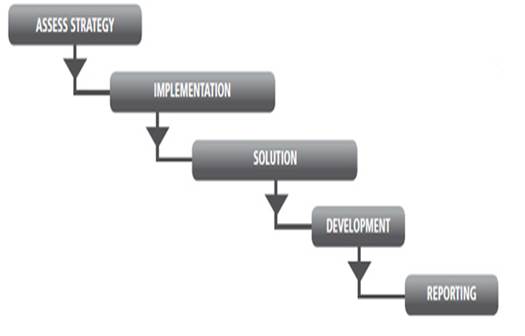

As with any decision-making process in a company, it’s important to have easy-to-follow steps in place that ensure you aren’t putting your business at a disadvantage in any way. And when it comes to managing the lifespans of equipment, you can’t afford to be caught unaware when an upgrade or full replacement is required. “Over time, almost all tech equipment becomes obsolete and you don’t want to be caught behind an overwhelming and costly equipment upgrade,” says Yuriy Petushkov, CEO at Baynetwork (www .baynetwork.com). “While there are many exceptions to the rule of becoming obsolete, it is best to stay on top of IT equipment by providing ongoing maintenance, gradual updates, and required replacements throughout the entire network. Lifecycle management makes or breaks business today, and you don’t want to be caught behind the eight ball or in the dust of your competition.”

There are other reasons why a hardware lifecycle management plan is important. If you know ahead of time that a piece of equipment is nearing EOL, you can sell it to third-party vendors and make some of your budget back by getting the “maximum value capture on IT assets and non-performing inventory,” says Michael Saia, president and CEO of XTechnology Global (www.xtglobal-usa.com).

“Over time, almost all tech equipment becomes obsolete and you don’t want to be caught behind an overwhelming and costly equipment upgrade,” says Yuriy Petushkov, CEO at Baynetwork

Tracking equipment & lifecycles

For your hardware lifecycle management plan to be truly successful, you have to determine what types of equipment need to be a part of your approach and what their average lifespans are. “Ideally all IT equipment should be tracked in an IT asset management tool that has automated discovery,” says Sandi Conrad, WCO (world-class operations) practice lead for Info-Tech Research Group (www.info-tech.com). “This will enable your asset team to get quick access to serial numbers [and] detailed component information, and report on virtualized as well as physical equipment.” In terms of lifespan, Conrad says that varies depending on use, but you can usually expect laptops to average three to four years, desktops to last four to five years, and servers to be optimal for about three to five years.

Knowing what pieces of equipment should be in your plan and their lifecycles are only two parts of the puzzle. Failure to consider this knowledge and to implement an overall equipment renewal or refresh plan earlier rather than later can result in unexpected overhauls that could cost your company extra. “The most practical approach is to calculate EOL for particular equipment and begin procurement for replacement of said equipment 18 months before full EOL has been reached,” says Petushkov. “This also applies to hardware replacement service license agreements and post-sales/extended support.” In essence, you need to overlap the lifecycle of existing equipment with potential new equipment purchases to avoid overspending and incurring unnecessary downtime.

Add more in depth details

Petushkov and Conrad agree that it’s important to know the lifespans of equipment in order to formulate a more reliable approach, but Petushkov also recommends using a Gantt chart, which he says is “the most effective way to plan ahead” and covers “all timelines associated to lifetime expectancy, maintenance, testing, upgrading, and replacement.” By taking much more than lifespans and new equipment purchases into account, you can make sure that your company is well prepared without jumping the gun on potentially expensive upgrades.

Petushkov also says that companies should look to updates or other solutions that can extend the life of their equipment instead of assuming that a wholesale replacement is necessary. “The hardware inventory is essential, but firmware and software are also critical considerations to keeping your equipment secure and up to date, which in some cases actually extends the life of the bare metal being used,” says Petushkov. If your company needs are being fully met by your existing infrastructure and future projections show that firmware and software upgrades will prolong the life of your equipment even with new technological breakthroughs, it might be more fiscally responsible for you to hold off on equipment purchases.

Looking to the future

As the final part of your hardware management plan, you must know how you will handle the disposal of old equipment when a new lifecycle begins. “Equipment disposal needs to be part of the plan,” says Conrad. “This may include lease returns or buyouts, cost recovery through an ITAD (IT asset disposition) company; it may include cascading of equipment to non-critical applications or low computing needs or may be disposal of equipment that has no life left in it. In any case, disposal needs to ensure environmentally safe recycling as well as security of data, where hard drives are wiped and potentially destroyed.”

“Equipment disposal needs to be part of the plan,”

Key points

Understand why you need a hardware lifecycle management plan and how it will help your company avoid potentially costly issues in the future.

Track every piece of equipment that will be a part of your lifecycle plan and know its respective lifespan.

Be as thorough as you can with your lifecycle management plan and include in-depth information whenever possible.

Look beyond procurement and management to also ensure that equipment disposal practices are environmentally safe and secure.